CO2 Performance ladder

Renewi uses a CO2-management system according to the CO2-Performance ladder level 4 and is certified for this. In this way we provide better insight, clear reduction targets, communication and participation in the chain and we contribute to a sustainable society. The CO2-Performance ladder is an instrument to stimulate companies to CO2-act consciously in your own business operations and in the chain. This involves energy saving, the efficient use of materials and the use of sustainable energy. The CO2Performance Ladder is managed by the Foundation for Climate-Friendly Procurement & Entrepreneurship (SKAO). The information and documents below demonstrate this method.

The ambition of Renewi is in line with the global objectives: to not exceed the 1.5*C warming of the planet. Renewi has committed to:

- reduce 15% of its Scope 1 and 2 by 2025 (FY26),

- reduce 50% of its Scope 1 and 2 by 2030 (FY31),

- 25% reduction on Scope 3

– all under absolute contraction approach, from the baseline year being the recalculated FY22. We consider these targets in line with the guidance of the Science-Based Targets Initiative although they have not been verified by SBTI yet.

Based on this new commitment, a detailed project planning for individual carbon reduction initiatives is under way. The general plans include:

- the decrease of fuel use and electrification of fleet,

- energy efficiency,

- energy sobriety,

- PV/wind/storage installation,

- Futher optimizing processes on site,

- Carbon capture.

A more detailed description of the performance, management system and planned actions can be found in the management reports:

Renewi follows the operational control rule in determining its GHG accounting boundary. The boundary of Renewi Netherlands Holding has been determined on the basis of the organization chart of Renewi in March 2024. Group Central Services are excluded from the below analysis as these activities support all legal entities, not just those that are being audited under CO2Prestatieladder. In due course of the suppliers analysis (A/C analysis) as prescribed by SKAO, we have identified that the Belgian business of Renewi, under Renewi NV entity, should be included in the CO2 Performance Ladder boundary going forward. This is reflected since the FY23 totals and going forward.

As a result of the activity above, the accounts given on this page for the purpose of CO2 Prestatieladder differ from the accounts presented in the Annual Report and the difference amounts to the operations of UK Municipal and the Group overheads.

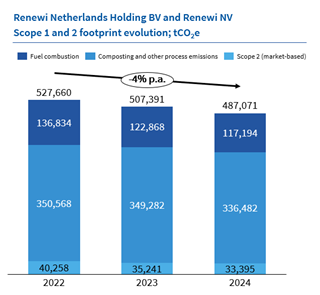

In FY24, a miscalculation in the base year was discovered, which triggered a revalidation of the limited assurance for the years FY22 and FY23 and a change in the numbers reported. The revalidated FY22 and FY23 figures, appropriated to the boundary described above, are presented below.

Renewi Netherlands Holding has restated the baseline emissions to 527,660 tons CO2e in FY22 (market-based). In FY23, the emissions dropped to 507,391 tons CO2e.

The total CO2e footprint for 2023 (excl. Scope 3) consisted of 93% scope 1 emissions and 7% scope 2 emissions. The decrease between 2022 and 2023 can be attributed to a decrease in tonnages, which explains lower process emissions as well as lower use of fuel. Additionally, continuous improvement activities have been performed around sites maintenance to improve the landfill gas capture and further optimization of routes through the Green Collective initiative.

The direct emissions (scope 1) caused by Renewi Netherlands and Renewi NV over FY23 amounted to 472,150 tonnes of CO2e and consisted in about 74% of direct process emissions (such as landfill gas, composting, soil cleaning process), and 26% of fuel consumption.

Within fuels, the most widely used one is diesel, in our CW NL and CW BE divisions, especially for fueling the trucks. Fuel consumed by lease cars is only responsible for only 0.5% of Scope 1.

The indirect CO2emissions (scope 2) for FY23 (market-based) amounted to 35,241 tCO2e and are almost entirely caused by purchased electricity on locations rather than in fleet. Note: at the moment the energy consumption of EV trucks is added to the site energy bills at the point of charging, therefore showing in the site-related electricity consumption.

Insight into the CO2 footprint FY24

Results of FY24 continue the decreasing trend: 487,071 tCO2e equals to nearly 4% reduction per annum. This can be attributed to several initiatives. The share of Euro 6 trucks increased from 77% up to 87%. Our fleet has also welcomed 8 new electrical vehicles in the last year and we continue exploring a larger role of the biofuels in our fuel mix. On the energy front, we saw an increase of the share of renewable electricity used on site from 35% up to 45.9% end FY24. This, combined with our continuous improvement’s activities and focus on optimizing our energy usage, and despite a 1.6% increase of electricity consumption on site, has largely contributed to a lower carbon intensity of our sites KPI which slightly decreased from 8.1 to 7.8 kg of CO2 per tonne of waste handled. Composting and other process emissions are dropping in line with tonnages.

Take a look into a detailed GHG and energy results

Contracts with award advantage

In FY24, the Commercial Waste Netherlands division has 9 contracts in which the CO2 Performance Ladder certificate was an important requirement. 1 of those was newly secured in FY24, with the CO2PL advantage as favourable, although not decisive criterion. Remaining 8 are the projects continued from the years past. Total carbon footprint of those projects per year is estimated not to exceed 5% of total carbon footprint of the division.

In Belgium, no CO2PL advantage contracts were won since Belgium was included in the certificate boundary in FY23.

Progress mid-year FY25

Due to our end-year data being audited to limited assurance level, the mid-year results are not published in full to maintain the same quality standards. A high-level directional brief is expected in December 2024.

You can see the half-yearly accounts of the previous years here.

Development projects in the value chain

We strive to be the leading waste-to-product company, and as such, we collaborate with partners and customers up and down the value chain to make the most impactful materials innovation happen.

Two of these projects have been presented on SKAO website as development projects and chain initiatives

- Renewi Nordsol and Shell focus on BioLNG

- Renewi, IKEA and Return mattress open fourth mattress recycling plant

- Renewi and PreZero continue to focus on Green Collective

Chain analyses

Renewi is aware of the influence of the company in the different chains, up and downstream, in which it acts. Based on this knowledge, Renewi identifies promising possible energy and CO2-reduction measures in the chains, and potential chain partners for tackling them. For two projects with chain partners, so-called chain analyses were carried out and the possible CO2-identified emission savings in the chain. Summaries of these two projects are available:

The CO2-performance ladder certificate can be found here.

To investigate the full profile of Renewi on SKAO website, please visit:

For an (archival) page of Renewi Westpoort Holding, please click here.