Innovation

The engine of your and our circular ambitions

Innovating for circularity

At Renewi, innovation is not just a value; it’s our promise for a circular economy. By continuously rethinking and improving our recycling operations, we move closer to our 75% recycling target for 2030, while saving CO2 and building a more sustainable future. Innovation at Renewi means developing new ideas, processes, and partnerships that converts most of the waste into valuable raw materials—turning today’s waste in new opportunities for the future.

Our innovation successes

Innovation isn’t just about big ideas—it’s about making everyday processes smarter, more sustainable, and more impactful for our stakeholders. We’re proud to share examples of how our innovative practices are making a tangible impact:

|

|

Extensive knowledge |

|

|

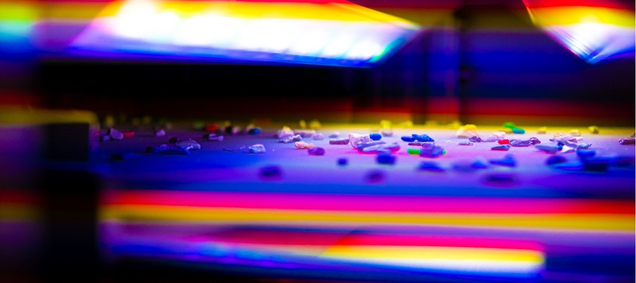

Advanced recycling |

|

|

Reduced carbon footprint |

|

|

Preservation of valuable resources |

Our commitment to continuous innovation

Innovation is at the core of our organic growth and strategic ambitions. It enables us to stay commercially agile while pioneering the circular economy. We invest in transformative technologies and foster partnerships that push the boundaries of what can be recycled.

Key focus areas

- Production of secondary raw materials: Enhancing the quality, consistency and volume of our circular materials through further development of our current recycling technologies.

- Advanced sorting: Using state-of-the-art technology to sort recyclates from mixed waste streams and reduce the amount of waste going to incineration.

- New recycling technologies:Creating or adopting new ways to derive value from waste streams that still go to incineration today.

By focusing on these areas, we are contributing directly to reducing carbon emissions, conserving raw materials, and creating a more circular economy.

Why and how we innovate

Renewi drives innovation as a broad and dynamic process that spans everything from applied research to operational pilots and industrial scale implementation. Our innovation efforts are aligned with clear goals that benefit our customers, society, and the environment:

- Economic gains: Production of high-value secondary raw materials that avoid incineration costs and taxes.

- Lower CO₂ emissions: Actively reducing Scope 3 emissions for our customers through use of secondary raw materials that replace fossil feedstock.

- Increased recycling volumes: Developing methods to recycle more materials that would previously have been incinerated or sent to landfill.

- Compliance and resource preservation:Ensuring compliance with the highest regulatory standards while safeguarding valuable raw materials.

- Minimising residual waste: Our approach is built on reducing residual waste to an absolute minimum and maximising recyclability.

A prime example of this vision in action is our advanced sorting line in Ghent, a state-of-the-art initiative demonstrating how innovation can lead to a reduction of 52% residual waste (April ‘23-April ‘24).

Advancing circularity together

If you have a groundbreaking idea or an innovative solution, we’d love to hear from you. Join us in advancing circularity together.